We introduce advanced

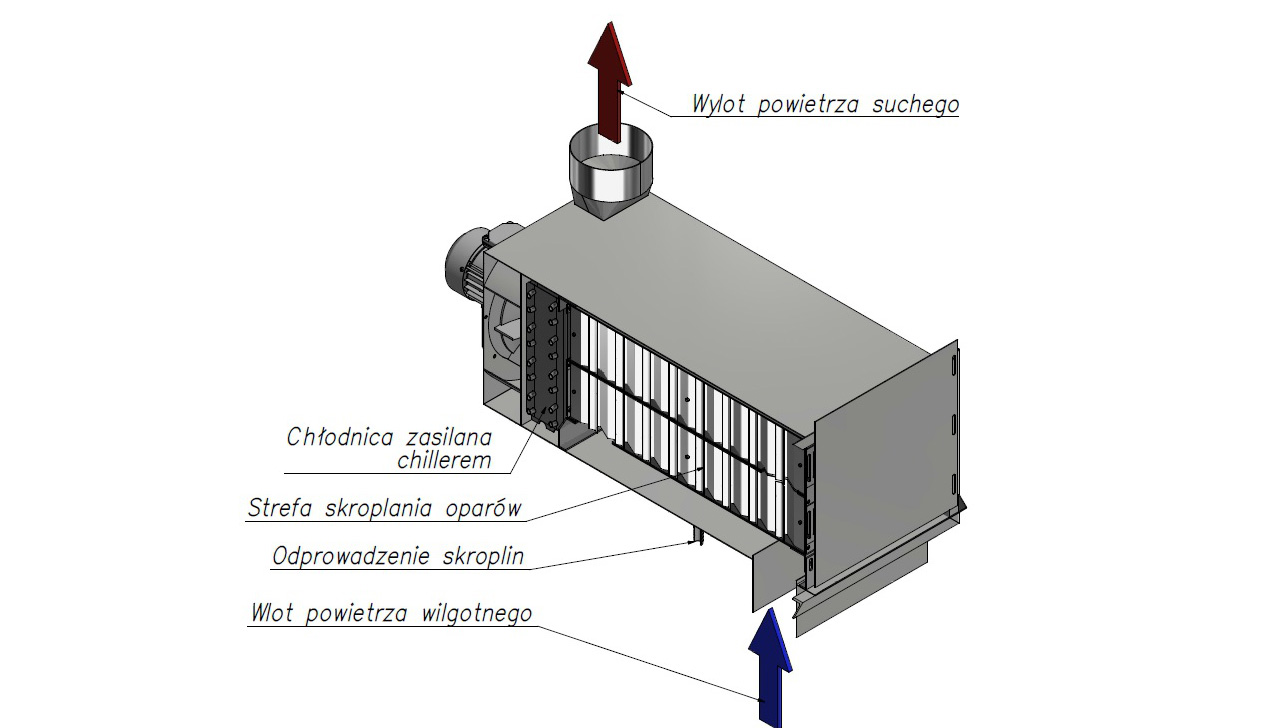

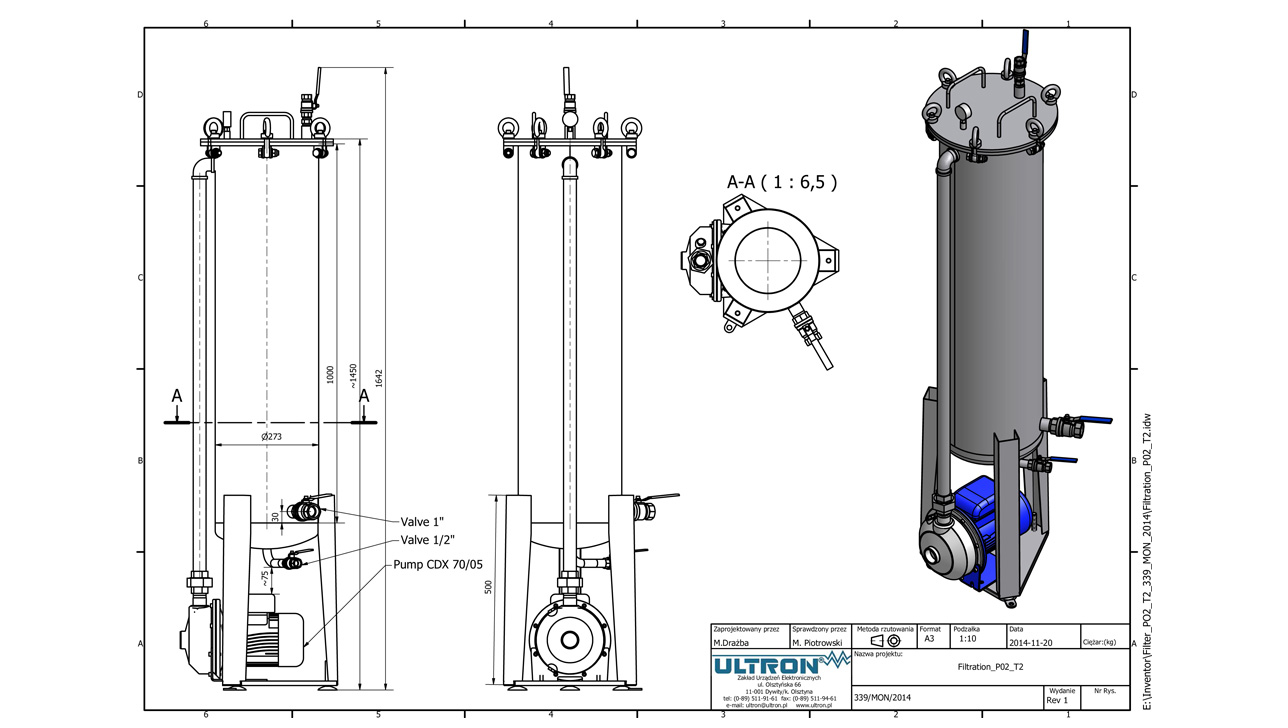

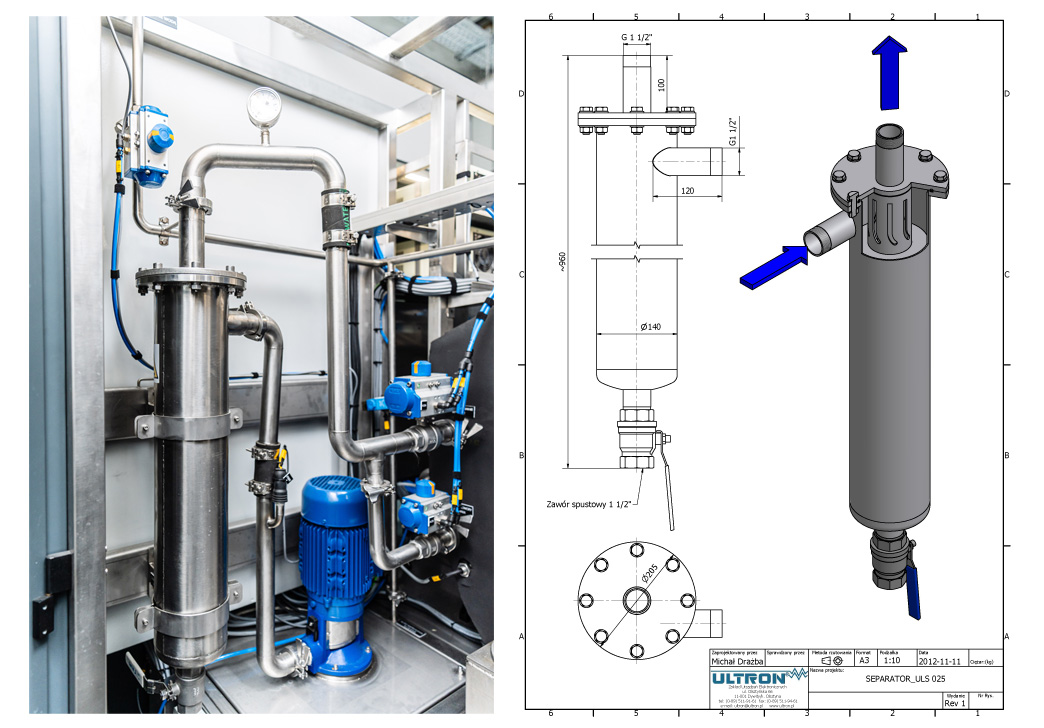

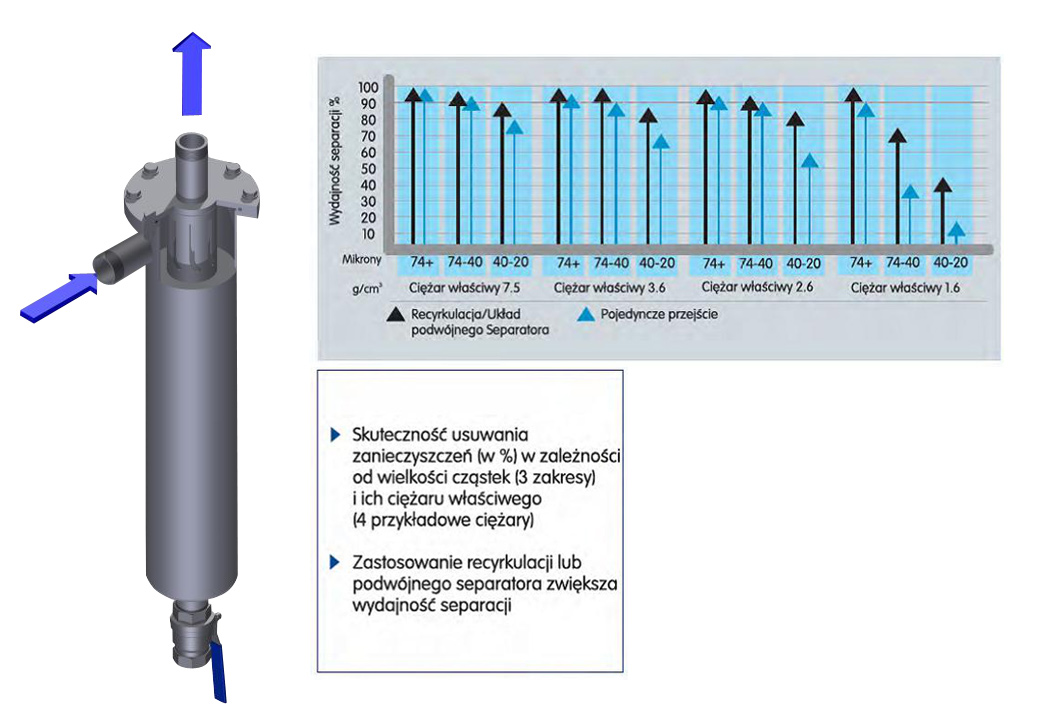

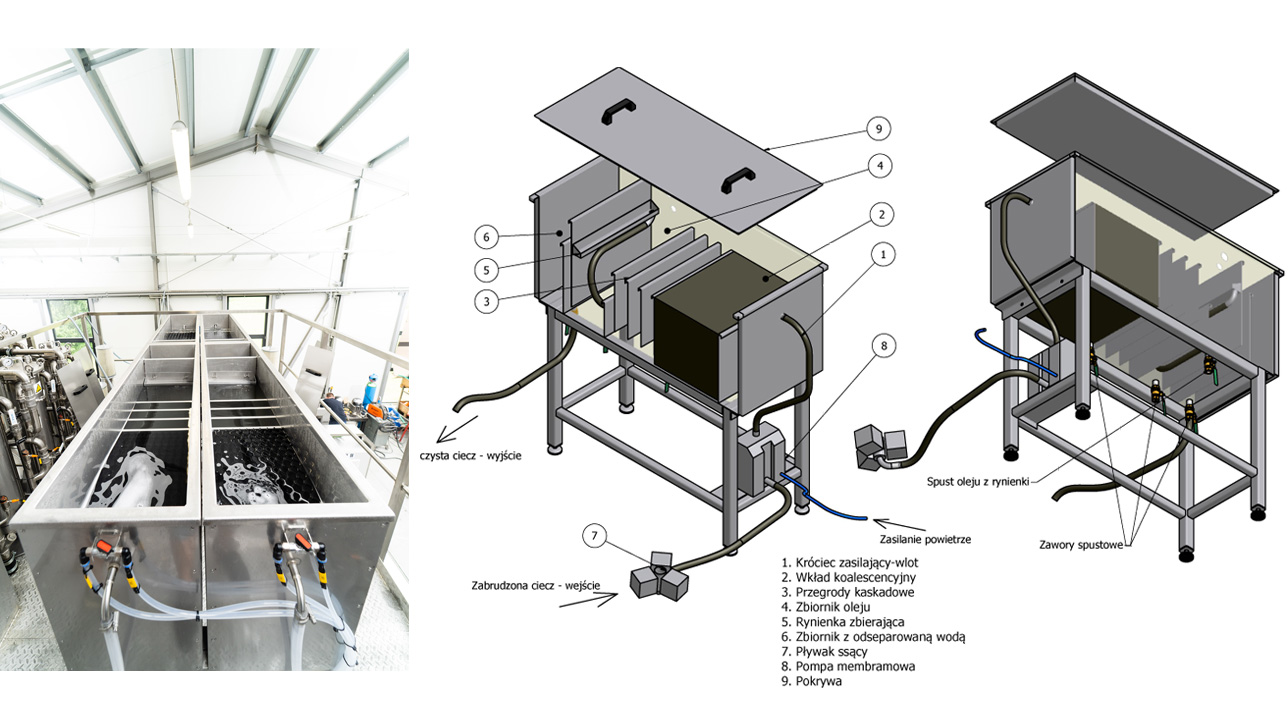

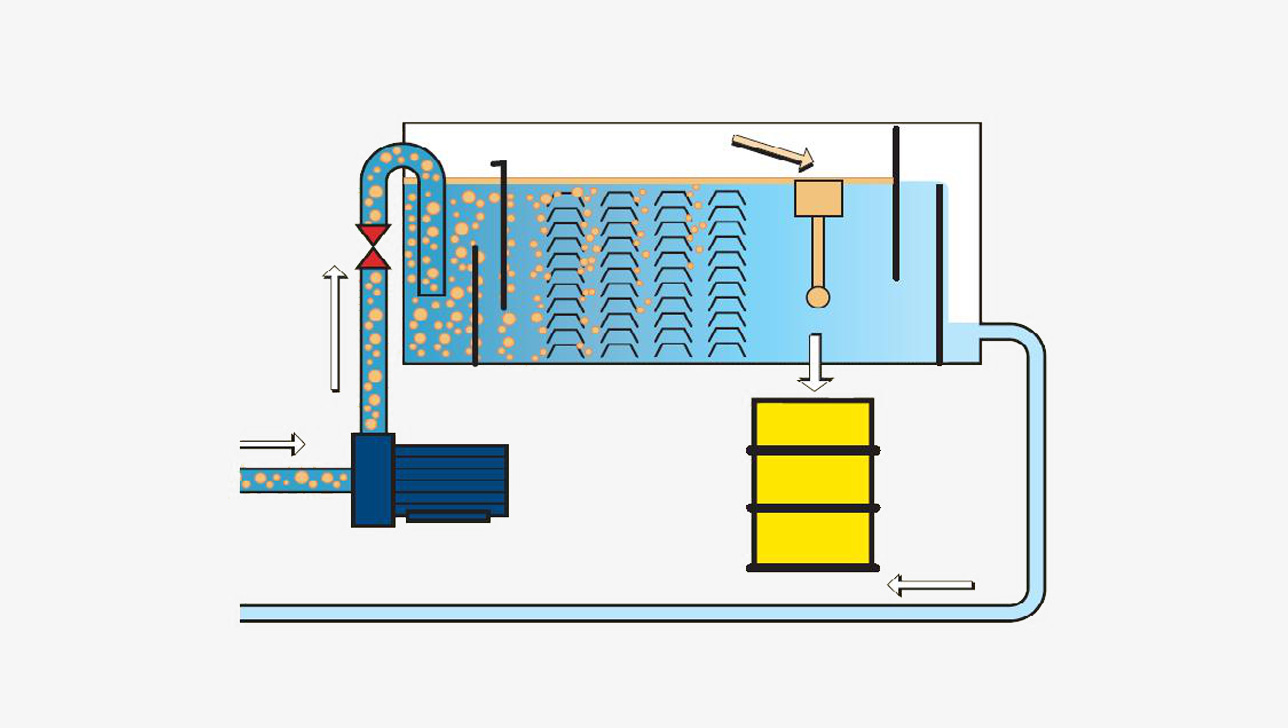

We introduce advanced solutions that facilitate production processes and minimise the use of energy and media. We can equip the unit with a heat pump, vapour condensation circuit, multi-stage precision filtration system, separation of oil contaminants, etc.